The casting process is the most common and cost-effective method for producing complex or large parts from prototype quantities to medium and high-volume production. It is used in a wide range of industries including agriculture, construction and mining equipment for both the commercial and private sectors.

Several different processes are available, each with its pros and cons for cost, metallurgical quality, volume production, dimensions held, durability and competitiveness. Choosing the right casting method is an iterative process that involves considering the product design and economics of each option.

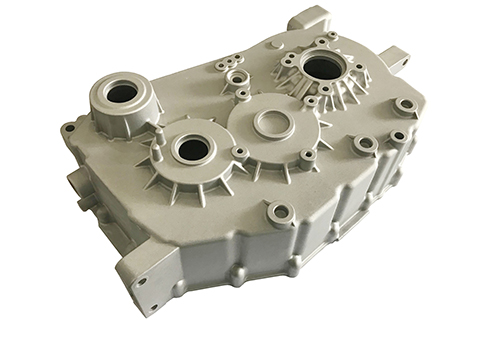

Permanent mold casting and die casting both use steel molds to form a cavity where molten metal can be forced into. However, they differ in how the molten metal enters the tooling and the type of cooling system.

With

permanent mold casting, a reservoir of molten aluminum is placed into a die and a gate controls the speed of flow. The die then enables a solid cavity to form as the aluminum melts. This cavity is sealed when the aluminum reaches a certain temperature and it cools to form the casting.

When choosing a casting method for your agricultural, construction and mining equipment needs, it is important to consider which material will best work for your application. The types of materials that are most commonly die-cast include aluminum, zinc, magnesium and copper.

CIC provides engineering solutions, cost efficient manufacturing, supply chain management and warehousing options to support all your agricultural and construction component needs. They provide a complete casting solution that meets or exceeds industry standards and delivers superior value to customers.

EN

EN