About of Automotive Transmission Transfer Box Die Casting Mould

An automotive transmission transfer box is a key component in a vehicle's drivetrain system that distributes power from the engine to the front and rear axles. A die casting mould is a tool used in the manufacturing process to create complex metal parts with high precision and accuracy.

In the context of automotive transmission transfer box production, a die casting mould is used to create the housing or casing that houses the transfer box components. The mould is typically made of steel and is designed to produce a specific shape and size of the casting with high repeatability.

The die casting process involves injecting molten metal, typically aluminum or zinc alloys, into the die casting mould under high pressure. The metal fills the mould cavity and solidifies, taking on the shape of the mould. The casting is then ejected from the mould and finished through additional machining and surface treatment processes.

The use of die casting moulds in automotive manufacturing allows for the production of high-quality, lightweight parts with complex shapes and tight tolerances. This makes it an ideal process for producing transmission transfer box housings that are strong, durable, and resistant to corrosion and other environmental factors.

Advantage of Automotive Transmission Transfer Box Die Casting Mould

The automotive transmission transfer box die casting mold offers several advantages in the manufacturing of transfer boxes for automobiles:

High production efficiency: Die casting molds are capable of producing high volumes of parts at a fast rate. This makes the manufacturing process more efficient and cost-effective.

Improved product quality: Die casting molds are capable of producing complex shapes with tight tolerances, resulting in products with high precision and consistency.

Reduced material waste: The die casting process is a near-net-shape process, which means that less material is required to produce the final product. This reduces material waste and makes the process more environmentally friendly.

Cost-effective: Die casting molds have a long lifespan and require minimal maintenance, making them a cost-effective option for high-volume production.

Versatile: Die casting molds can be used to produce a wide range of transfer box designs, making them a versatile option for automotive manufacturers.

Overall, the use of automotive transmission transfer box die casting molds offers numerous advantages for automotive manufacturers, including increased efficiency, improved product quality, and reduced costs.

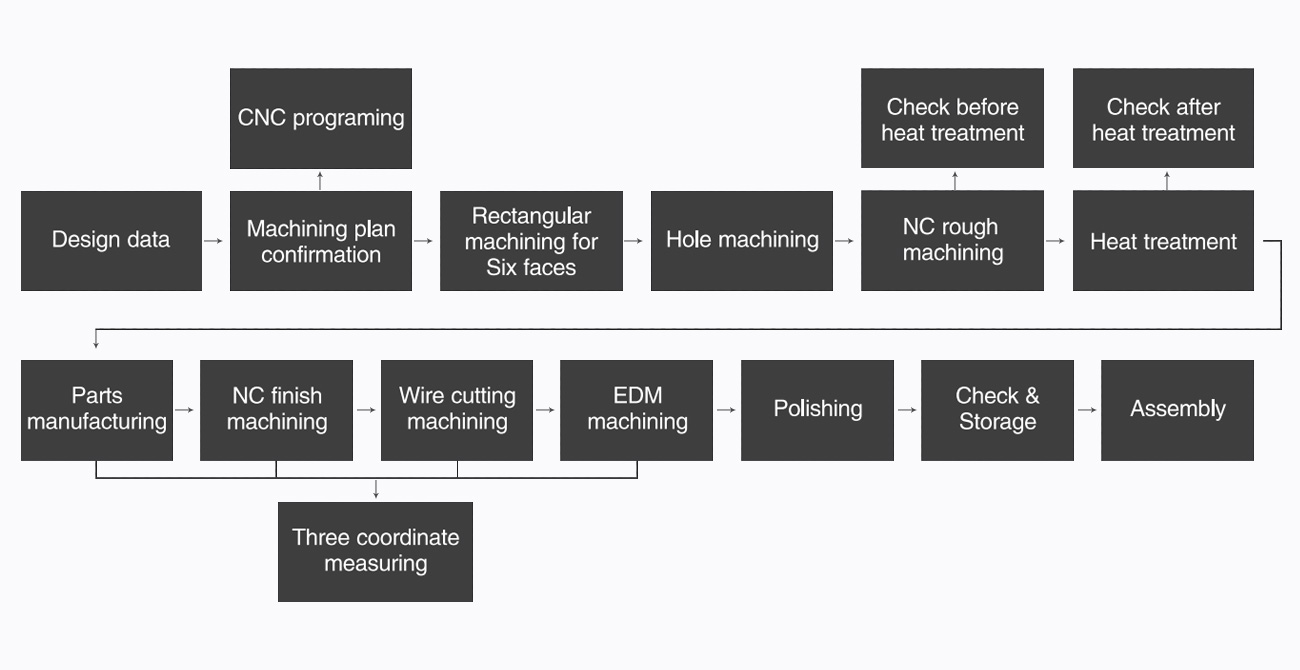

Automotive Transmission Transfer Box Die Casting Mould production process

The production process for an automotive transmission transfer box die casting mold typically involves several stages, including:

Design: The first stage in the production process is designing the mold. This involves creating a 3D model of the mold based on the specifications provided by the client.

Mold Making: Once the mold design is finalized, the next step is to manufacture the mold. This involves the use of advanced machining tools and techniques to create the mold cavity and other necessary features.

Die Casting: With the mold completed, the next stage is the actual die casting process. This involves melting the metal alloy, such as aluminum or zinc, and injecting it into the mold cavity. The metal is allowed to cool and solidify, after which the mold is opened to reveal the final product.

Finishing: After the die casting process is complete, the castings are cleaned and trimmed to remove any excess material or debris. Surface treatments, such as shot blasting, painting or polishing, may also be applied to improve the appearance and durability of the final product.

Inspection and Testing: The final stage involves the inspection and testing of the castings to ensure that they meet the required specifications and quality standards. This may involve visual inspections, dimensional measurements, or functional testing, depending on the intended application of the transfer box. Any defects or deviations from the specifications are identified and corrected before the final product is released for use.

EN

EN