What is Die Casting Mould Yacht Engine Parts

Die casting moulds for yacht engine parts are tools used in the die casting process to produce high-quality, precise, and complex engine parts used in yachts. The moulds are designed and manufactured to withstand high pressure and temperature during the casting process.

The die casting process for yacht engine parts involves the use of molten metal, typically aluminum or zinc, which is injected under high pressure into a die casting mould. The mould is made up of two halves, the cavity and the core, and together they form the shape of the final part. Once the molten metal is injected into the mould, it is allowed to cool and solidify before being removed from the mould.

Die casting moulds for yacht engine parts must be designed to produce parts with high strength and durability, as well as high precision and accuracy. The moulds must be able to withstand the high temperatures and pressures involved in the die casting process and produce parts that meet the stringent requirements of the marine industry.

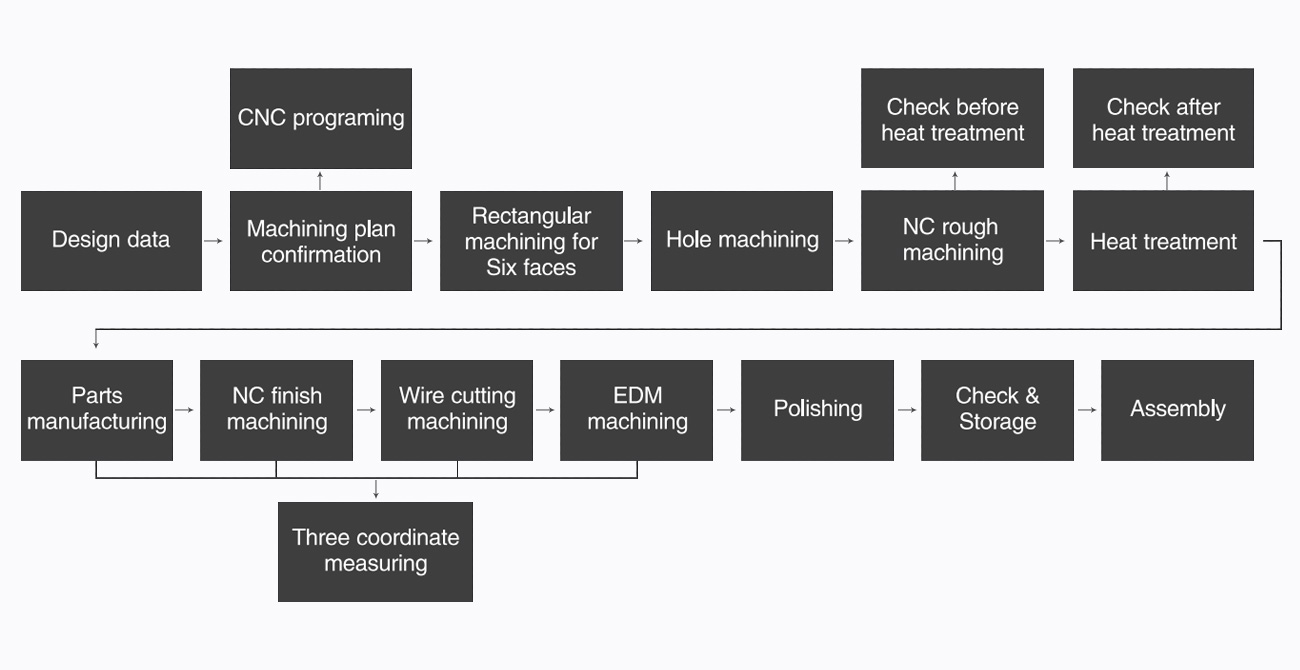

To achieve high-quality yacht engine parts, the die casting mould must be carefully designed and manufactured using advanced technologies and techniques. The mould design should be optimized for the specific part to be produced and take into account factors such as material flow, cooling rate, and part ejection.

Overall, die casting moulds for yacht engine parts are crucial tools in the manufacturing process, allowing for the production of high-quality parts that meet the exact specifications and requirements of the marine industry.

What are the advantages of Die Casting Mould Yacht Engine Parts

There are several advantages of using die casting moulds for yacht engine parts. Here are some of them:

High precision and accuracy: Die casting moulds allow for the production of high-precision and accurate parts with very tight tolerances. This is essential for yacht engine parts, which need to fit together precisely to function properly.

Complex geometries: Die casting moulds can produce complex shapes and geometries that would be difficult or impossible to achieve using other manufacturing methods. This is particularly important for yacht engine parts, which often have intricate designs and features.

High strength and durability: Die casting produces parts with high strength and durability, making them suitable for use in demanding marine environments. This is important for yacht engine parts, which must withstand the rigors of constant exposure to saltwater and other harsh conditions.

Cost-effective: Die casting moulds are a cost-effective option for producing large quantities of yacht engine parts. The high production rates and low unit costs make die casting an attractive option for the marine industry.

Reduced waste: Die casting produces very little waste material, making it an environmentally friendly option for yacht engine parts production. The leftover material can be recycled and reused in the production process.

Overall, the advantages of using die casting moulds for yacht engine parts include high precision, complex geometries, high strength and durability, cost-effectiveness, and reduced waste. These benefits make die casting a popular choice for manufacturing high-quality yacht engine parts that meet the stringent requirements of the marine industry.

EN

EN