Precision Engineering: Creating the Perfect Sewing Machine Die Casting Mould

Precision engineering is critical when creating a sewing machine die casting mold. A die casting mold is used to create precise components that are used in the sewing machine. The quality of the mold will directly impact the quality and consistency of the finished components.

Here are some key factors to consider when creating the perfect sewing machine die casting mold:

Material selection: The material used to create the mold must be strong, durable, and resistant to wear and tear. Typically, high-quality tool steel or aluminum alloys are used to create the mold. The material must also be able to withstand the high pressures and temperatures associated with the die casting process.

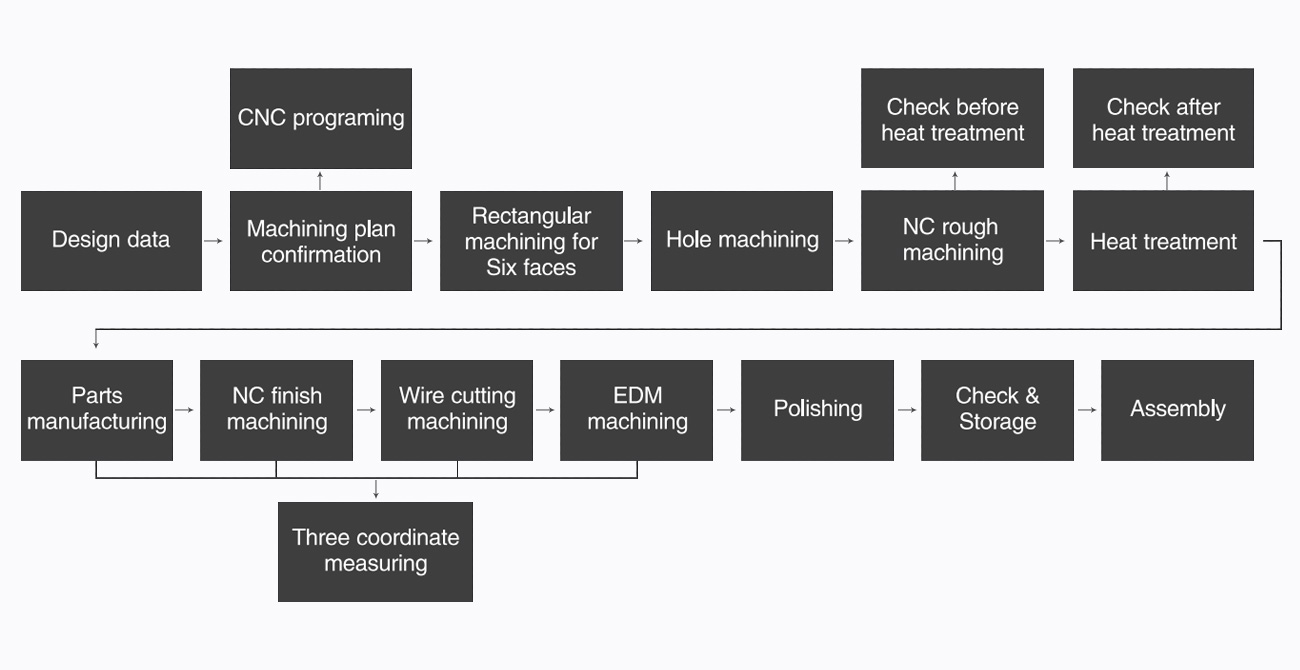

Precision machining: The mold must be machined with a high level of precision to ensure that the finished components meet the required specifications. This involves using advanced machining techniques and equipment to create complex shapes and contours.

Surface finish: The surface finish of the mold is critical to ensure that the finished components are of high quality. The surface finish should be smooth and free of defects such as pits, scratches, and burrs.

Cooling system: The cooling system is critical to ensure that the mold can withstand the high temperatures associated with the die casting process. The cooling system must be designed to efficiently remove heat from the mold and maintain a consistent temperature throughout the process.

Quality control: Quality control measures must be implemented throughout the manufacturing process to ensure that the finished mold meets the required specifications. This involves rigorous testing and inspection to detect any defects or flaws in the mold.

Overall, precision engineering is essential when creating a sewing machine die casting mold. By paying close attention to material selection, precision machining, surface finish, cooling system, and quality control, manufacturers can create molds that produce high-quality, consistent components for use in sewing machines.

Advantages of Sewing machine Die Casting Mould

There are several advantages to using die casting molds for sewing machine components:

High precision: Die casting molds are designed to create components that are precise and accurate, which is important for sewing machine components that require tight tolerances.

High production rate: The die casting process is fast and efficient, allowing for a high production rate. This means that manufacturers can produce a large number of components in a short amount of time.

Cost-effective: Die casting molds are typically more cost-effective than other manufacturing methods, such as machining or forging. This is because the process requires less material and produces less waste.

High strength: Components produced using die casting molds are typically stronger and more durable than those produced using other manufacturing methods. This is because the process allows for the creation of complex shapes and internal structures that can improve strength and durability.

Versatility: Die casting molds can be used to produce a wide range of sewing machine components, including gears, housings, and brackets, among others. This versatility allows manufacturers to use the same mold for multiple components, which can save time and money.

Overall, die casting molds offer a range of advantages for sewing machine components. They are precise, efficient, cost-effective, strong, and versatile, making them an ideal choice for manufacturers who want to produce high-quality components quickly and efficiently.

EN

EN