Factors to be considered in Agricultural Machinery Parts Slewing shell/Interpolation arm Mould

The manufacturing of agricultural machinery parts such as slewing shells and interpolation arms requires high-quality molds that can produce accurate and consistent components. Here are some key factors to consider when designing a die casting mold for agricultural machinery parts:

Material selection: The material used to create the mold must be strong, durable, and able to withstand the high pressures and temperatures associated with the die casting process. High-quality tool steel or aluminum alloys are commonly used for this purpose.

Part design: The design of the agricultural machinery part is the first consideration when designing the mold. The mold must be designed to create a component that is accurate, consistent, and meets the required specifications.

Mold design: The mold design must be optimized for maximum efficiency and productivity. This includes considerations such as the number of cavities, gating and venting, and the cooling system.

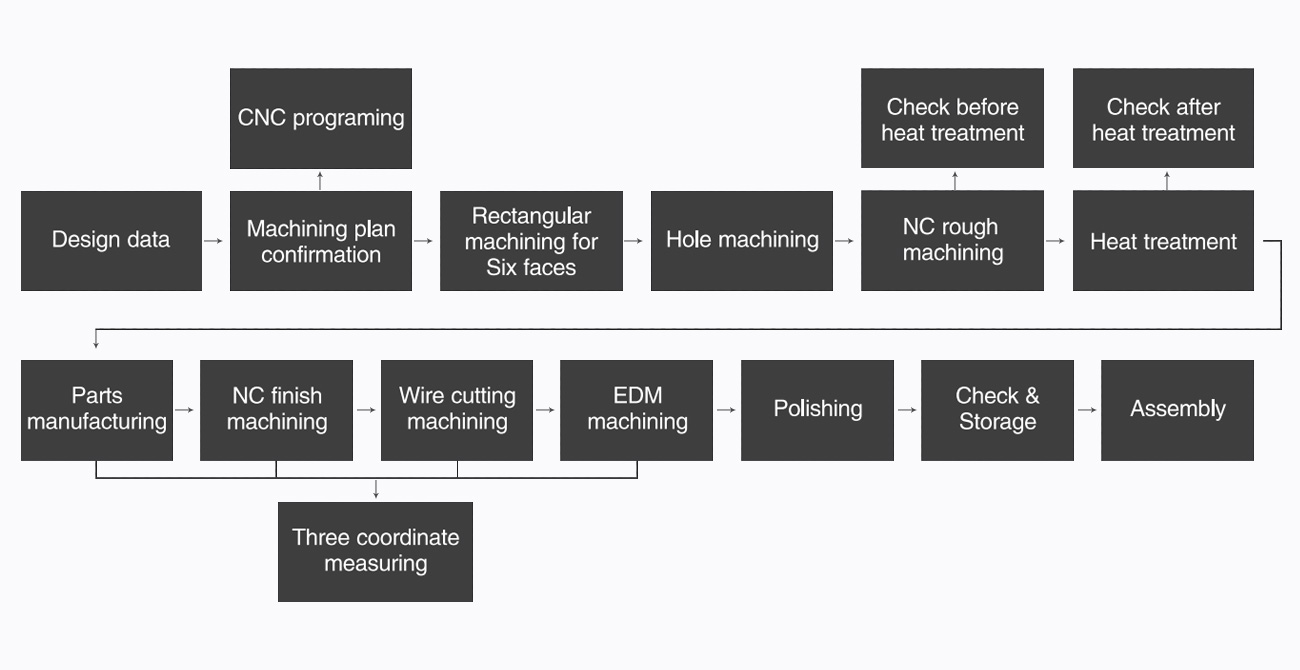

Manufacturing process: The manufacturing process must be designed to optimize efficiency and productivity. This includes considerations such as the speed of the die casting process, the quality of the material feed system, and the cooling time required for the mold.

Quality control: Quality control measures must be implemented throughout the manufacturing process to ensure that the finished mold and components meet the required specifications. This includes rigorous testing and inspection to detect any defects or flaws in the mold or finished components.

By considering these factors when designing a die casting mold for agricultural machinery parts, manufacturers can create high-quality molds that produce accurate, consistent, and reliable components. This can help to improve efficiency and productivity in the manufacturing process and ensure that the finished agricultural machinery is of the highest quality.

What are the characteristics of the Agricultural Machinery Parts Slewing shell/Interpolation arm Mould

The characteristics of a high-quality die casting mold for agricultural machinery parts, such as slewing shells and interpolation arms, include the following:

Precision and accuracy: The mold must be designed to create components that are precise and accurate, with tight tolerances and consistent dimensions. This is critical for agricultural machinery parts, which must fit together perfectly to ensure optimal performance.

Durability: The mold must be made from a strong and durable material that can withstand the high pressures and temperatures of the die casting process. The material used should also be able to resist wear and tear, ensuring that the mold remains in good condition even after multiple casting cycles.

Efficiency: The mold should be designed for maximum efficiency, with a fast casting cycle and minimal waste. This can help to reduce production time and costs, while also improving the overall quality of the finished components.

Versatility: The mold should be versatile enough to be used for multiple types of agricultural machinery parts, including slewing shells and interpolation arms, among others. This can help to reduce the need for multiple molds and increase production efficiency.

Quality control: The mold must be subject to rigorous quality control measures, including inspection and testing, to ensure that the finished components meet the required specifications. This is critical for ensuring that the agricultural machinery parts are of the highest quality and perform optimally.

By ensuring that the die casting mold for agricultural machinery parts has these characteristics, manufacturers can produce high-quality components that are precise, durable, efficient, versatile, and of the highest quality.

EN

EN