Introduction of the Vehicles Battery Energy Storage Device Parts Controller housing Mould

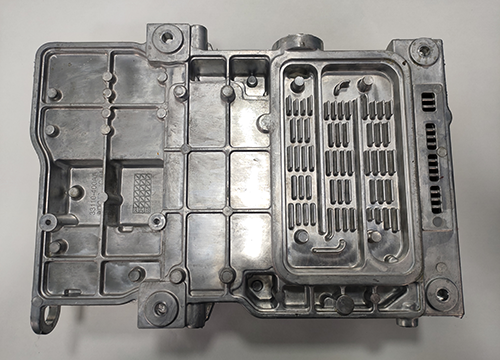

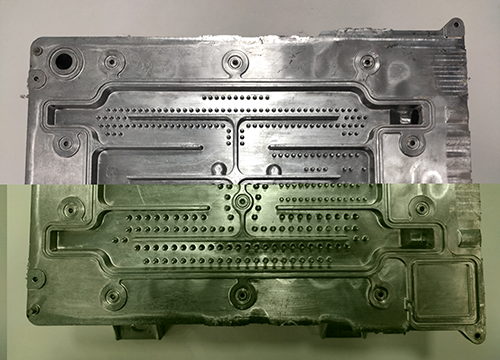

The Vehicle Battery Energy Storage Device Parts Controller Housing Mould is a specialized tool used in the production of parts for battery energy storage devices used in electric vehicles. The mold is designed to create the housing for the controller, which is a key component of the energy storage device.

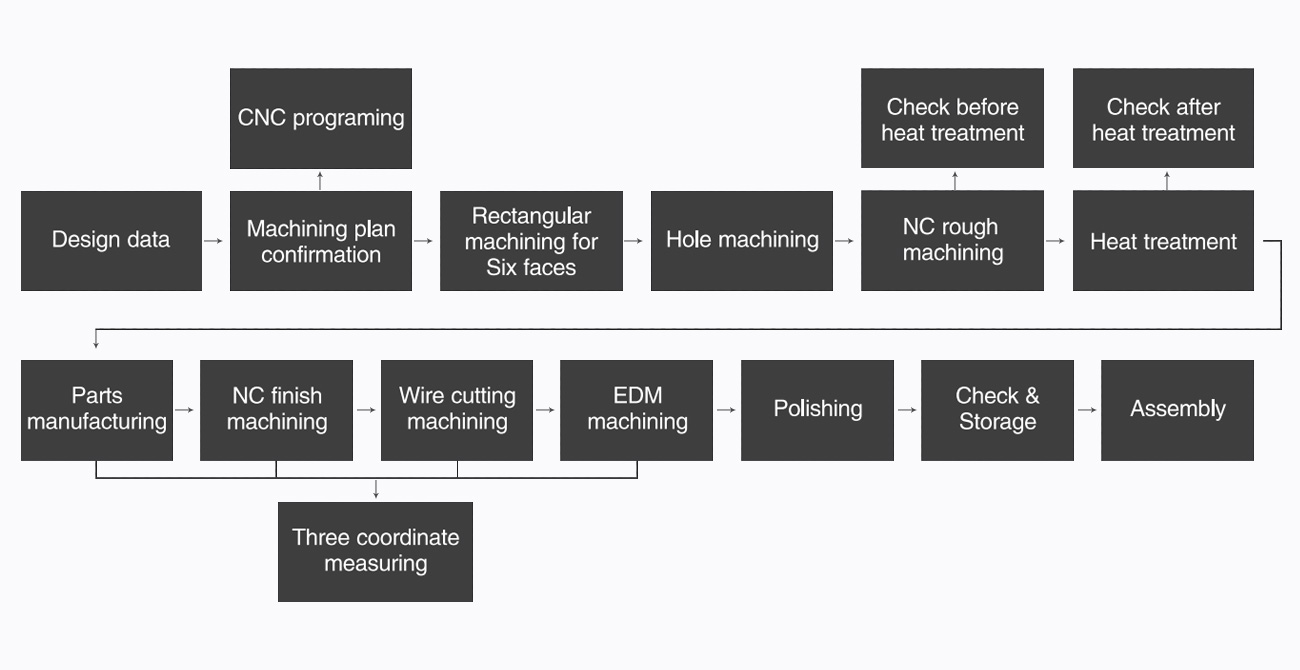

The mold is typically made of high-quality steel and is designed to withstand the high temperatures and pressures required in the molding process. It is precision-machined to ensure accuracy and consistency in the final product. The mold is typically made up of two halves, which can be opened and closed using a hydraulic or mechanical system.

The mold is an essential component in the production of battery energy storage device parts. It allows manufacturers to produce high-quality, precise parts at a high volume and with great efficiency. By using a mold, manufacturers can ensure that each part is identical, which is crucial for the reliable operation of the energy storage device.

Overall, the Vehicle Battery Energy Storage Device Parts Controller Housing Mould is a critical component in the production process for electric vehicle parts. Its use ensures the production of high-quality, reliable parts that are essential to the functioning of electric vehicles.

Advantage of the Vehicles Battery Energy Storage Device Parts Controller housing Mould

The use of a Vehicles Battery Energy Storage Device Parts Controller housing Mould offers several advantages, including:

Cost-effective production: By using a mould, the production process becomes more streamlined and cost-effective as the same mould can be used to produce multiple identical parts, thus reducing the need for manual labour and the associated costs.

High precision: The moulding process ensures a high level of precision and accuracy in the production of parts, which is critical for the proper functioning of the energy storage device.

Consistency: As the same mould is used to produce multiple parts, the parts are consistent in their shape, size, and quality, which is important for the proper assembly and functioning of the device.

Durability: The use of high-quality materials in the moulding process ensures that the parts produced are durable and long-lasting, reducing the need for frequent replacements.

Customization: The mould can be designed to produce parts that are specific to the requirements of the energy storage device, allowing for customization and flexibility in the design and production process.

Overall, the use of a Vehicles Battery Energy Storage Device Parts Controller housing Mould is a cost-effective, efficient, and reliable way to produce high-quality parts for energy storage devices.

Application Fields of Vehicles Battery Energy Storage Device Parts Controller housing Mould

The application fields for a vehicles battery energy storage device parts controller housing mould include:

Automotive Industry: The most obvious application for a vehicle battery energy storage device parts controller housing mould is in the automotive industry. The mould is used to create the housing for the controller which controls the flow of electricity from the battery to the vehicle.

Renewable Energy Storage: Battery energy storage devices are used to store energy from renewable sources such as solar panels or wind turbines. The controller housing mould can be used to create the housing for the controller which regulates the flow of energy in and out of the battery.

Industrial Equipment: Battery energy storage devices are also used in industrial equipment such as forklifts, cranes and other heavy machinery. The controller housing mould can be used to create the housing for the controller which regulates the flow of electricity to power the equipment.

Overall, the controller housing mould has a wide range of applications in industries that rely on battery energy storage devices to power their equipment or devices.

EN

EN