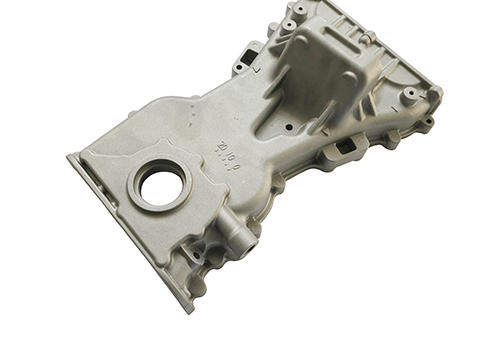

What is the Automotive Sprocket Cover Die Casting Mould?

The automotive sprocket cover die casting mould is a specialized tool used in the manufacturing of sprocket covers for automotive engines through the process of die casting. A sprocket cover is a protective cover that is fitted over the sprocket, which is a toothed wheel that transfers power from the engine to the chain or belt that drives the wheels.

The die casting process involves forcing molten metal, typically aluminum or zinc, into a metal mold or die under high pressure. The metal then solidifies in the shape of the mold, creating a precise and accurate part with a smooth surface finish.

The sprocket cover die casting mould is designed to produce sprocket covers that meet the specific requirements of the automotive industry, including dimensional accuracy, strength, durability, and heat resistance. The mold is typically made of high-grade steel and is carefully engineered to ensure that it produces consistent and high-quality parts with each cycle of the die casting process.

Overall, the automotive sprocket cover die casting mould plays an essential role in the mass production of high-quality sprocket covers for the automotive industry.

Features of Automotive Sprocket Cover Die Casting Mould

The features of an automotive sprocket cover die casting mould can vary depending on the specific design and requirements of the part being produced. However, some common features that are typically found in these types of molds include:

High durability: The mould is made of high-grade steel that can withstand the high pressures and temperatures of the die casting process, ensuring a long service life.

Accurate dimensional control: The mould is designed to produce parts with precise dimensional accuracy, ensuring that each sprocket cover fits perfectly with the engine and other components.

Consistent quality: The mould is engineered to produce consistent and repeatable parts, ensuring that every sprocket cover meets the same high standards of quality and performance.

Efficient cooling: The mould is designed with an efficient cooling system to ensure that the molten metal solidifies quickly and evenly, reducing cycle times and improving productivity.

Easy maintenance: The mould is designed for easy maintenance and repair, with replaceable components that can be quickly and easily swapped out as needed.

Overall, the automotive sprocket cover die casting mould is a precision tool that is essential for producing high-quality sprocket covers for the automotive industry, with features designed to ensure accuracy, consistency, and durability.

Application field of Automotive Sprocket Cover Die Casting Mould

Some common application fields of the automotive sprocket cover die casting mould include:

Passenger cars: Sprocket covers are widely used in passenger cars to protect the engine's drive system and to reduce noise and vibration.

Commercial vehicles: Sprocket covers are also commonly used in commercial vehicles such as trucks and buses to protect the engine's drive system and ensure efficient operation.

Motorcycles: Sprocket covers are essential components of motorcycle engines, protecting the drive chain or belt and ensuring reliable performance.

Off-road vehicles: Sprocket covers are also used in off-road vehicles such as ATVs and dirt bikes, where they play a crucial role in protecting the drive system from mud, dirt, and other debris.

Overall, the automotive sprocket cover die casting mould is a versatile tool that is used in a wide range of applications within the automotive industry, ensuring that engines operate smoothly, efficiently, and reliably.

EN

EN