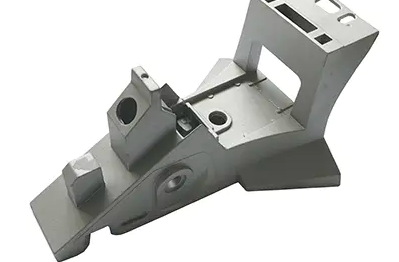

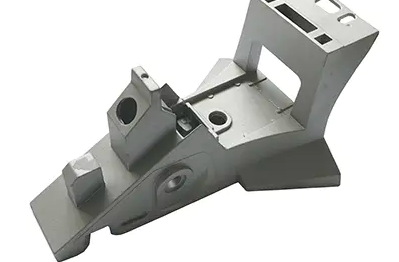

Die casting molds are critical components in the manufacturing of sewing machines, as they help to create precision parts that are essential for the proper functioning of the machine. The science behind die casting molds involves a combination of engineering principles, materials science, and manufacturing processes that ensure that the final product meets the required specifications.

The die casting process involves melting a metal, typically aluminum or zinc, and injecting it into a mold under high pressure. The mold is designed to create a specific shape, and the molten metal is forced into the mold cavity, where it solidifies and takes on the shape of the mold.

The quality of the die casting mold is critical to the success of the process, as it determines the accuracy and precision of the final product. The mold must be designed to ensure that the molten metal flows evenly into all areas of the mold cavity, and that there are no air pockets or other defects that could compromise the integrity of the final product.

Materials science is also a critical component of the die casting mold manufacturing process. The mold must be made from a material that is durable and can withstand the high temperatures and pressures involved in the die casting process. Common materials used for die casting molds include tool steel, H13 steel, and aluminum.

Manufacturing processes also play a crucial role in the creation of high-quality die casting molds. Computer-aided design (CAD) software is often used to create the mold design, and computer-aided manufacturing (CAM) is used to create the mold itself. CNC machining is often used to create the mold cavity, which requires a high degree of precision to ensure that the final product meets the required specifications.

Overall, the art of precision in

sewing machine die casting molds involves a combination of engineering, materials science, and manufacturing processes that must work together seamlessly to create a high-quality product. By using advanced technology and adhering to strict quality control standards, manufacturers can create precision molds that help to produce high-quality sewing machines that are reliable and efficient.

EN

EN