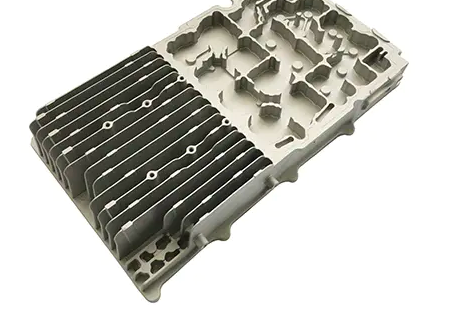

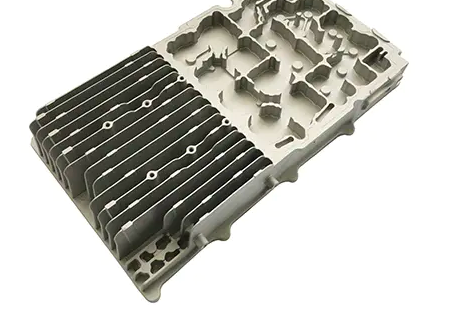

Communication Filter Parts Mold is a type of mold used in the manufacturing process of communication filter parts. Communication filter parts are components used in various communication devices and systems, such as cell phones, radios, and antennas. The mold is designed to produce these parts in large quantities with high precision and accuracy.

Here are some key features of Communication Filter Parts Mold:

Precision: The mold is designed to produce communication filter parts with high precision and accuracy, ensuring that the parts are consistent in size and shape.

Durability: The mold is made of high-quality materials that can withstand the high pressure and temperature required in the injection molding process. This ensures that the mold can produce large quantities of parts without deteriorating quickly.

Customizable: The mold can be customized to produce communication filter parts in different shapes, sizes, and materials to meet the specific needs of different applications.

Cost-effective: Injection molding is a cost-effective manufacturing process that can produce large quantities of parts quickly and efficiently. The use of a mold in the process further reduces the overall cost of production.

Efficiency: The use of a mold in the injection molding process ensures that each cycle produces multiple parts, increasing the efficiency of the manufacturing process.

Overall, Communication Filter Parts Mold is a versatile and efficient tool for the production of communication filter parts. It can produce parts with high precision and accuracy, and can be customized to meet the specific needs of different applications. The use of a mold in the injection molding process also makes it a cost-effective and efficient manufacturing process.

EN

EN