- +86-574 86146666

- [email protected]

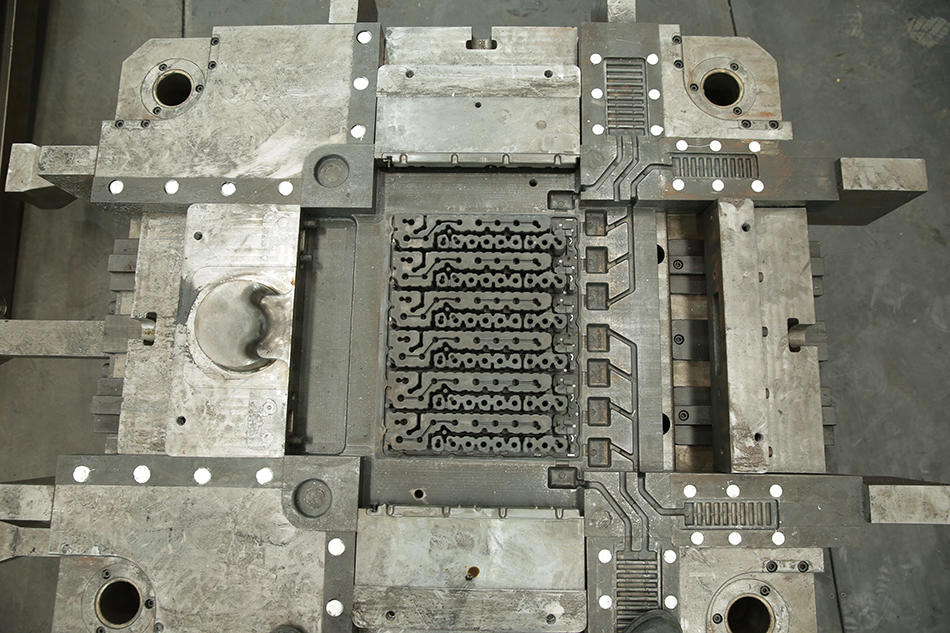

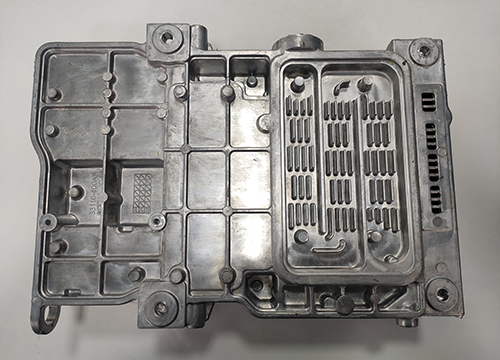

- Die Casting Mould Manufacturing

- Home

- About

- Product

- Automobile mould

- Automotive Sprocket Cover

- Automotive Engine Bracket

- Automotive Brake

- Automotive Oil Pump Cover

- Automotive Engine Cover

- Automotive Water Pump Housing

- Automotive Oil Pan

- Automotive Steering Wheel Housing

- Automotive Connecting Box Shell

- Automotive Clutch Housing

- Automotive Car Receiving Box

- Automotive Engine Housing

- Automotive Transmission Transfer Box

- Communication parts

- Robot parts

- Sewing machine

- Agricultural machinery

- LED lamp housing

- New energy vehicles

- Others parts

- Automobile mould

- Service

- News

- Contact

EN

EN